The news about the assembly of another Chinese car at an empty factory is not surprising: close ties with the Celestial Empire are the key to the survival of the Russian car industry. However, the Sollers site in the economic zone “Alabuga” stands out against the general background: the original JAC managed to be modernized, and they switched from “screwdriver” assembly to full-cycle production. Why Sollers Atlant is better than the “Chinese”, and how Aurus influenced the vans – in our report.

After Ford left, the Sollers car plant in Tatarstan was not empty for long: just nine months after the cessation of supplies of European spare parts in the Alabuga economic zone, they began to produce commercial vehicles under their own brand. Nine months later, Sollers organized full-cycle production with welding and body painting.

JAC became a partner of the Russian company, and the format of cooperation is atypical: Sollers concluded an exclusive agreement with the Chinese side and received the right to make changes to the design without approval. In fact, Sollers Atlant is a separate branch of JAC Sunray development, because since last year, an updated family of cars has been produced in China with other engines, a modified body and interior.

Although the Atlant family includes both trucks and minibuses, there are still the most all-metal vans on the conveyor

Sergey Ilyin

Sollers Sales and Marketing Director Marat Sharapov confirmed that the Russian automaker is “tired of interrupted partnerships”, so now the focus is not on licensed assembly, but on the development of its own product with the gradual localization of key components: body stamping, gearbox and engine.

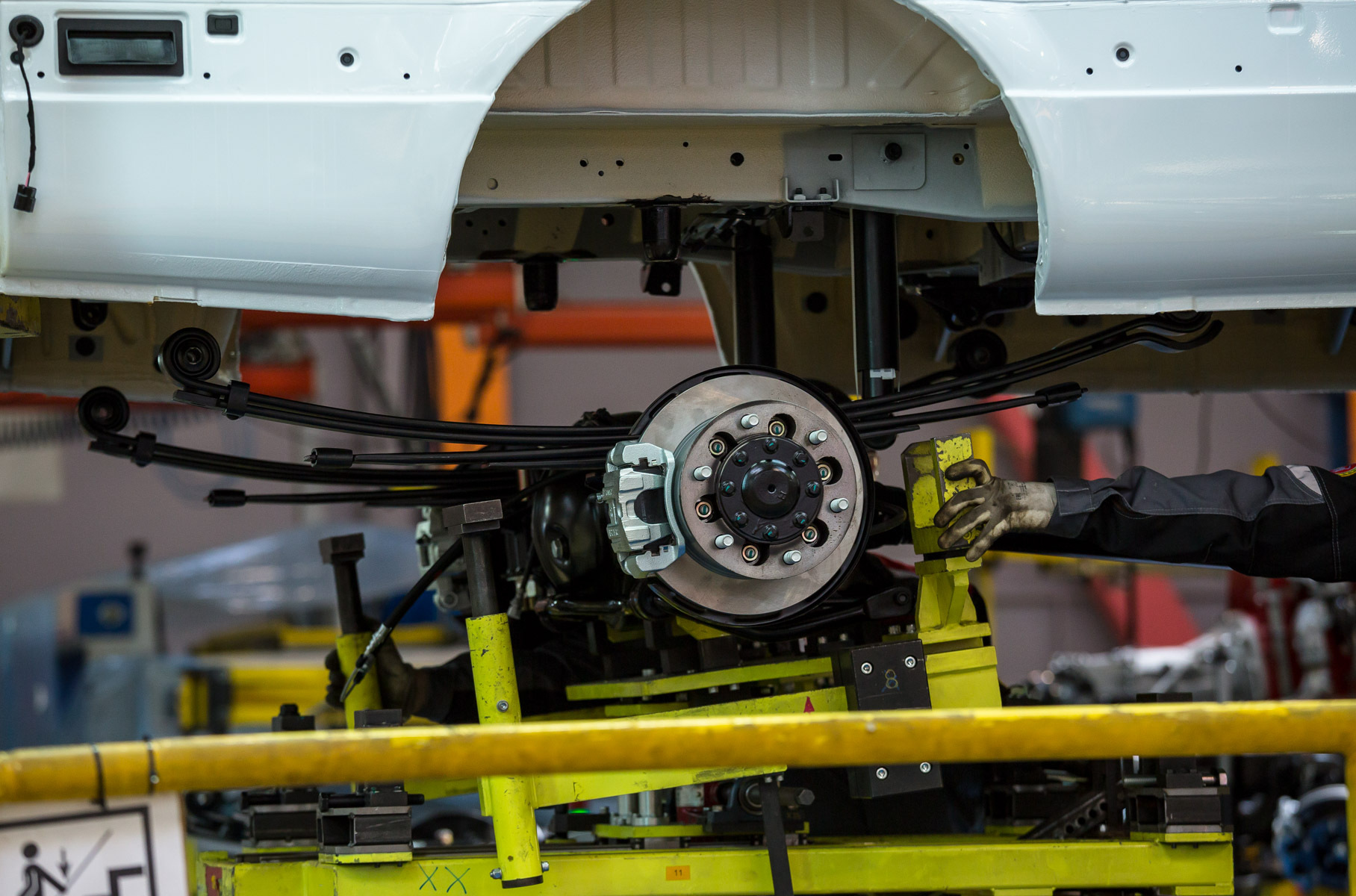

The Atlant family has already moved away from the original model: welding, anti-corrosion treatment and painting processes have been improved, “warm” options have been included in the basic package, reinforced springs and an additional battery have been added. In the future, Sollers vans and minibuses will have an automatic transmission, hard-wired all-wheel drive, and even a new base engine.

Sergey Ilyin Sergey Ilyin

Sergey Ilyin Sergey Ilyin

Sergey Ilyin Sergey Ilyin

Sergey Ilyin Sergey Ilyin

Sergey Ilyin

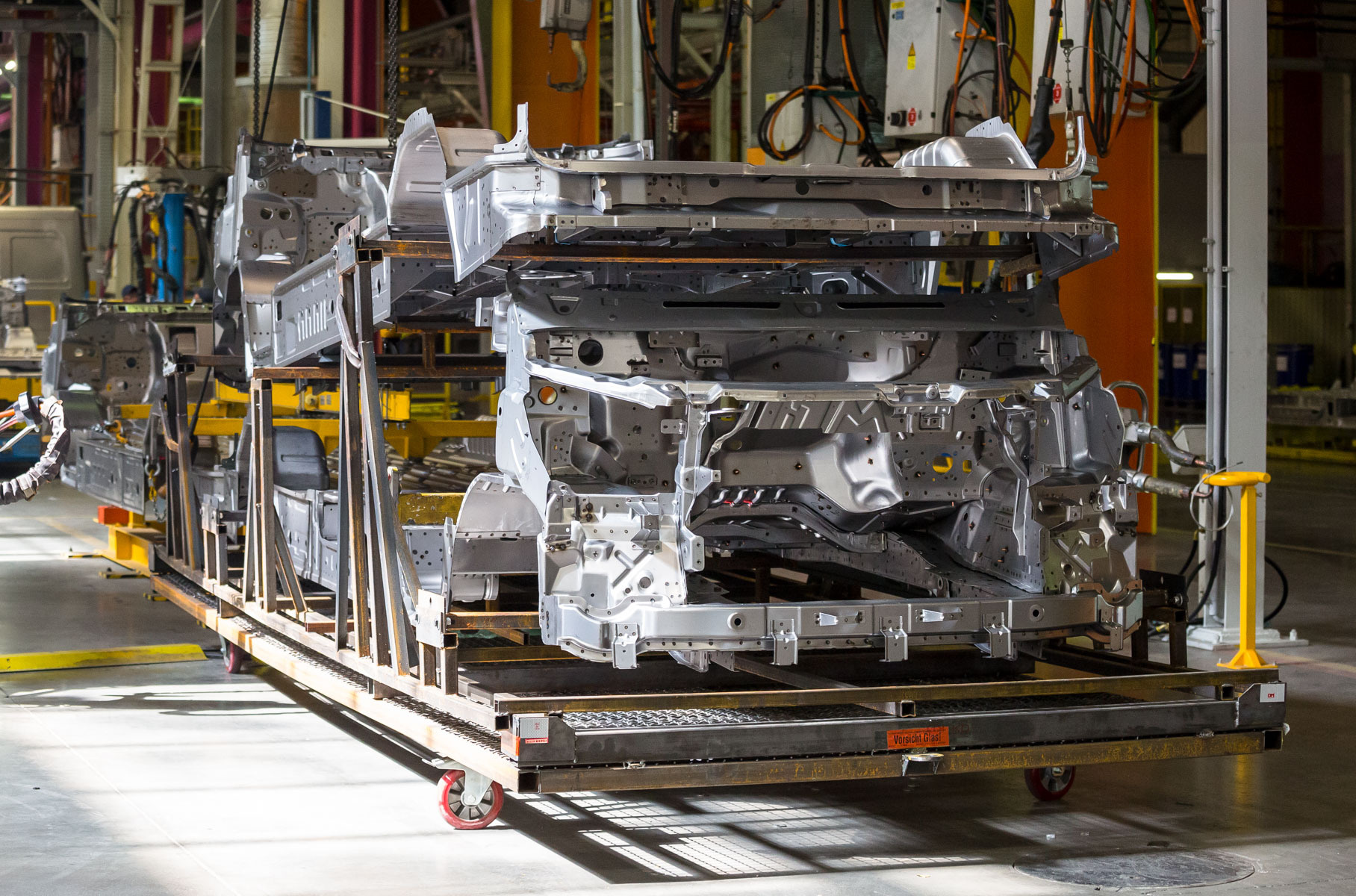

Acquaintance with the Sollers plant began with a welding shop. The process is automated, but the software for all 36 robots is written by Sollers staff. The bodies of Atlant vans, Aurus Komendant crossovers and Aurus Senat sedans are welded on the same conveyor line! Commercial vehicles only benefit from being next to premium models.

The welding process at Sollers is different from JAC technology. Firstly, all seams are glued: this increases the tightness of the joints and prevents corrosion. Secondly, cavity waxing and mastic coating have been added. Finally, quality control has changed. A separate room with a vibration-proof foundation was built for the measuring robots. The geometry of the body is checked by a special three-coordinate mechanism.

The robot checks the welds in the doorway of the van

Sergey Ilyin Sergey Ilyin

Sergey Ilyin Sergey Ilyin

Sergey Ilyin Sergey Ilyin

Sergey Ilyin

There is another way to test the quality of welded joints. Once a month, the bodies are literally torn to pieces: metal should be destroyed, not welded points. On the example of a deformed body, one can clearly see the filling of hidden cavities and the coating of the inside of the spars.

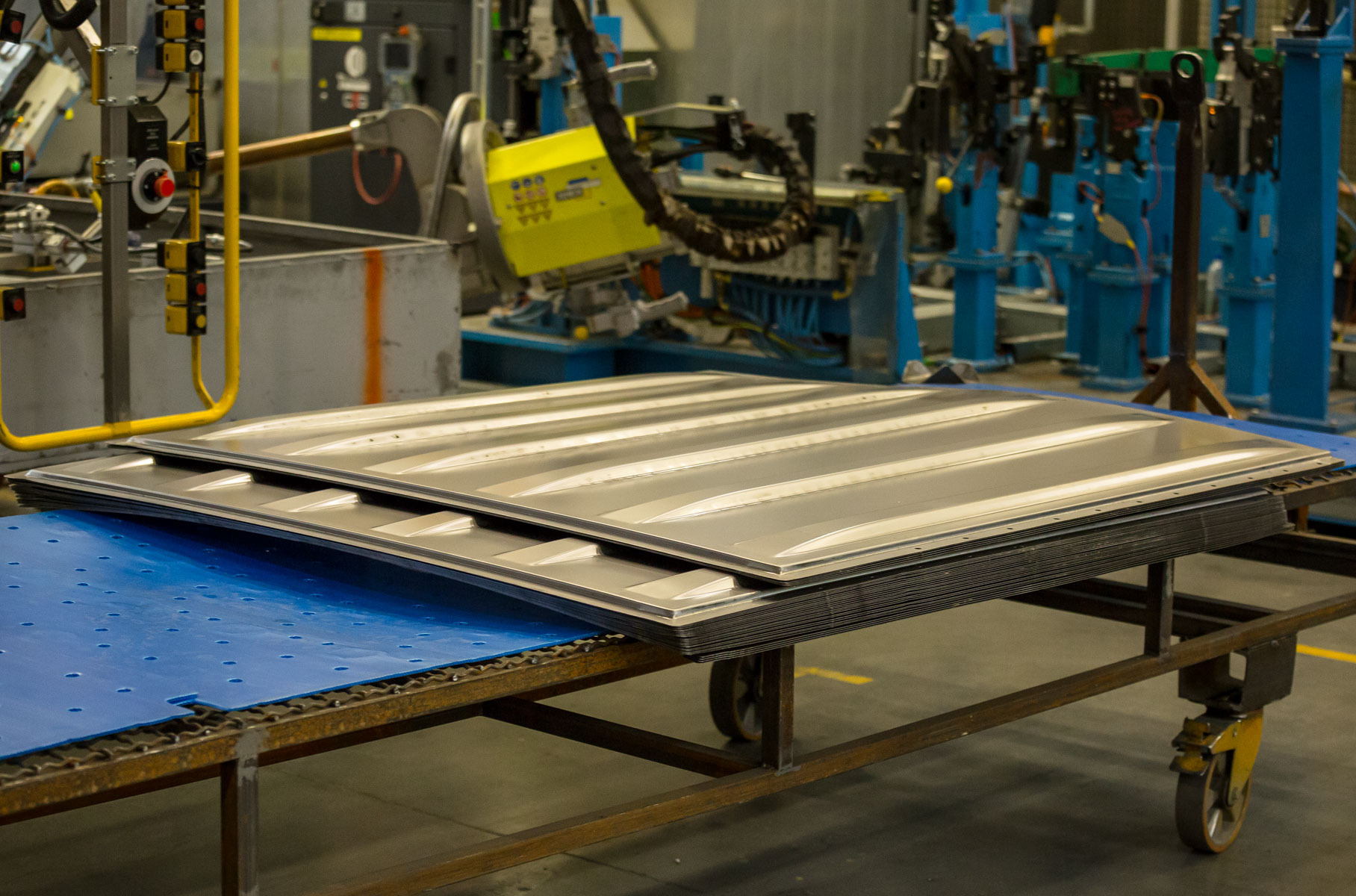

The bodies of Sollers are painted by the electrostatic method – according to the technology of passenger cars. The paint layer is twice as thick (120 microns versus 60 on JAC vans), and the robots apply paint not only from the outside, but also from the inside. This is not surprising, because together with the “Atlantes” the factory paints “Auruses”! Interestingly, the mechanism takes only 15 seconds to change the paint, but so far it is not often necessary to change colors: most cars are white.

Sollers is considering extending the paintwork warranty to seven years, as rust protection is given increased attention.

Sergey Ilyin Sergey Ilyin

Sergey Ilyin Sergey Ilyin

Sergey Ilyin Sergey Ilyin

Sergey Ilyin

Sollers insists that there are no problems with paints: there are seven colors in the range, including bright blue and sand. However, most customers prefer white cars, and the factory is just adjusting to customers. At the Elabuga plant, they emphasize that they basically do not work “for storage”: all cars are assembled taking into account the wishes of dealers and end users.

The production “neighborhood” of utility vans and luxury sedans is not seen anywhere else.

Sergey Malachite green Aurus Komendant diluted the dull range of white and black cars

Malachite green Aurus Komendant diluted the dull range of white and black cars

Sergey Ilyin Sergey Ilyin

Sergey Ilyin They also paint Atlantes in bright colors: here is a van in a corporate color for a well-known marketplace

They also paint Atlantes in bright colors: here is a van in a corporate color for a well-known marketplace

Sergey Ilyin

An unusual stand, even by world standards, on which Sollers bodies are selectively driven – the Air Flow test for tightness. Both Atlantes and Auruses are checked in the cell. All openings (including technological ones) are closed with plugs, and then the car is pumped with air or smoke: for a better search for leaks. The test allows you to identify loose seals, make design changes and improve acoustic comfort.

Sergey Ilyin

Sergey Ilyin

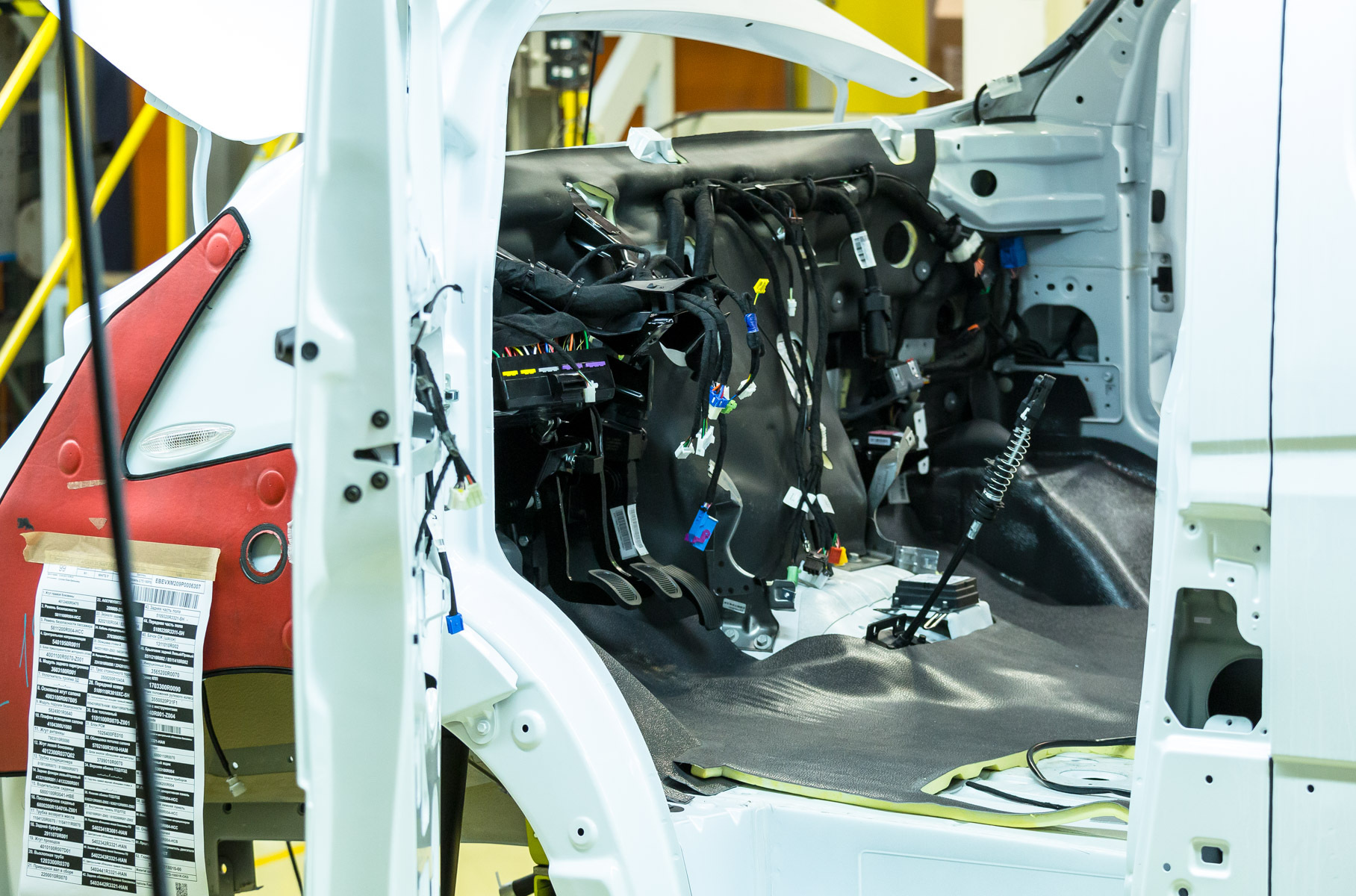

The final stage of production is assembly. Here, the main operations are also entrusted to electronics: fasteners are tightened with a precisely specified moment, at the right angle, for a certain number of turns. The line between the engine module and the bodywork is mostly men, but this is the exception rather than the rule: there are more women in other areas.

Viktor Zornikov, director of technological development and industrialization at Sollers, believes that women are more responsible, attentive and reliable. As for physical strength, it is not needed at the factory: the maximum mass that a worker needs to lift is five kilograms. All labor-intensive operations are performed by automation: unmanned vehicles move loaded carts, attach wheels, move already assembled units along the conveyor.

Sergey Ilyin Sergey Ilyin

Sergey Ilyin Sergey Ilyin

Sergey Ilyin Sergey Ilyin

Sergey Ilyin Sergey Ilyin

Sergey Ilyin

Finished machines are carefully checked: first, specialists inspect the product from the outside and record the smallest defects in a log, then trucks, vans and minibuses are waiting for a sprinkler chamber, a shaker and a short but very uneven test track. On the road with an imitation of a railway crossing, a cobblestone pavement and a bumpy country road, journalists managed to pass, and they provided the whole range of models: from a light base van with a 1.9 engine to a heavy refrigerated truck with dual tires.

Sergey Ilyin Sergey Ilyin

Sergey Ilyin Sergey Ilyin

Sergey Ilyin Sergey Ilyin

Sergey Ilyin

A trip behind the wheel on a two-hundred-meter section with bumps cannot be called a test drive, but some conclusions can be drawn. Even the “younger” 1.9 engine (139 hp, 310 Nm) is high-torque enough that fourth gear can be turned on at 25 kilometers per hour, reducing the speed almost to idle. On an empty car, even uphill, you practically don’t have to gas it up. Extraneous noises on the test track did not cut the ear, and yet the empty van cannot be called quiet. If we ignore the noise, then the driving experience is like in a passenger car: light steering, excellent visibility, good selectivity of the gearbox.

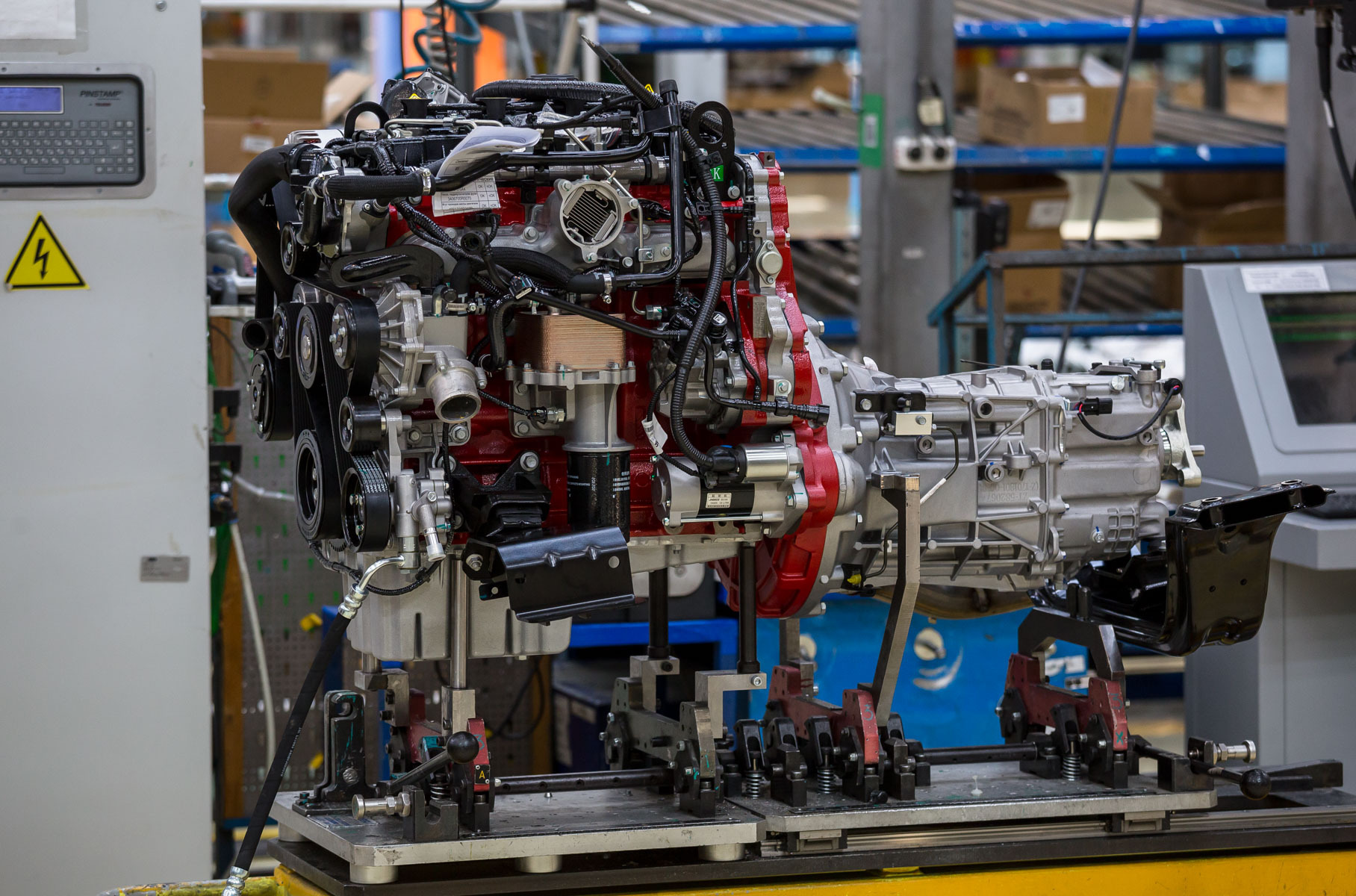

Test assembly of the 2.7 turbodiesel in Alabuga is already underway, but journalists have not yet been allowed into the engine plant

Test assembly of the 2.7 turbodiesel in Alabuga is already underway, but journalists have not yet been allowed into the engine plant

Sergey Ilyin

The age of Atlantes with a 1.9 engine may not last long: Sollers thought about unifying the base van with the Argo truck and UAZ all-terrain vehicles. This means that a turbodiesel with a working volume of 1999 cubic centimeters (130 forces, 285 Nm) will appear under the hood. This unit is less powerful and flexible, however, after the localization of production in Russia, its installation should be more profitable than importing a 1.9 engine from China. Sollers plans to produce attachments for engines in Russia, switch to domestic casting and machining.

An example of successful import substitution is domestic Kama tires. The problem with the lack of wheel arch liners is promised to be solved in the near future.

An example of successful import substitution is domestic Kama tires. The problem with the lack of wheel arch liners is promised to be solved in the near future.

Sergey Ilyin

A complete rejection of imports is not an end in itself: Sollers adheres to a logistical and financial approach and does not pursue localization points. For example, it is more expedient to buy bridges for Atlanta in China. The goal for 2024 is to switch to Russian stamping of body parts, organize the production of engines and a manual transmission. In the long term, Sollers commercial vehicles will have LED headlights, automatic transmission and ADAS driver assistance systems. But the Atlants are in no hurry to unify the rear lights, doors, fenders and bumpers: it hurts a lot of trouble with re-certification.

Sollers vans and minibuses are only at first glance the same: in fact, there are two completely different versions of the stern

Sergey Ilyin Sollers vans and minibuses are only at first glance the same: in fact, there are two completely different variants of the stern

Sollers vans and minibuses are only at first glance the same: in fact, there are two completely different variants of the stern

Sergey Ilyin

Less than a year has passed since the restart of the plant, but Sollers hopes that the Russian-Chinese vans will be as successful as the Ford Transit. In 2023, they plan to produce at least ten thousand cars, in the future – to increase the annual volume to 40 thousand units. In the light commercial vehicle market, Sollers plans to increase its share to 40 percent. The result of June 2023 is seven percent, although the situation is different in the segment of all-metal vans: the contribution of Atlanta is a significant 25 percent, only GAZelle-NEXT sells better.

Heavy van with an extra long wheelbase and a high roof in the corporate color of cash-in-transit vehicles. The armored cars were not shown to journalists.

Heavy van with an extra long wheelbase and a high roof in the corporate color of cash-in-transit vehicles. The armored cars were not shown to journalists.

Sergey Ilyin

Market prospects for Sollers Atlant will depend on reliability and price. The plant is proud that although the share of armored versions in total sales (as of August 2023) reaches ten percent (about 700 vehicles out of 7000), not a single serious breakdown has been recorded. As for the price lists, they have not been rewritten since the beginning of the year: the base Atlant still costs 2.9 million rubles. As production is localized, dependence on imports and currency fluctuations will be even less. Perhaps, over time, Sollers Atlant will become more Russian than Chinese? /m